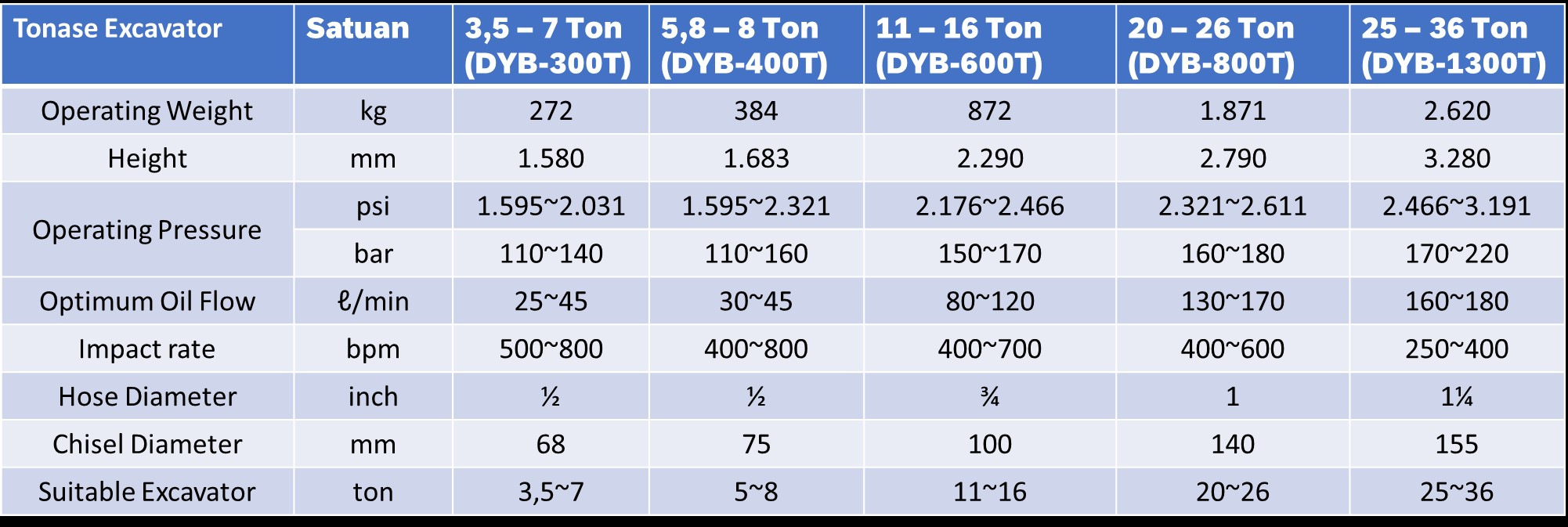

Hydraulic Breaker

Here is the top type series of hydraulic breakers which is provided by PT Istana Berkat Sejahtera

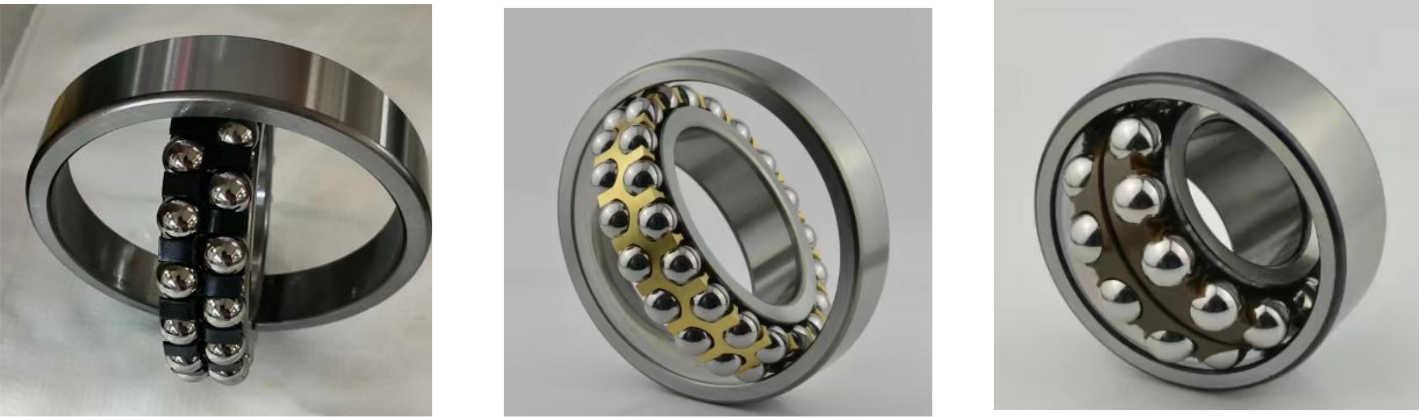

Bearings & Seals

Here is standard bearing list which we offer:

- Deep Groove Ball Bearing

- Self Aligning Ball Bearing

- Angular Contact Ball Bearing

- Thrust Ball Bearing

- Thrust Roller Bearing

- Needle Roller Bearing

- Slewing Bearing

- LM Guide (liner motion guide) / Ball Screw

Deep Groove Ball Bearing

open without seal

rubber seal

steel seal

nylon cage

brass cage

ceramic

Special purpose bearings

Special bearings for vibration applications are exquisitely designed, possessing several notable advantages, including:

High Vibration Tolerance: capable of withstanding extremely high vibration levels, maintaining stable performance.

Misalignment Tolerance: effective operation even in misaligned conditions.

High Load Capacity: exceptional ability to bear heavy loads.

Low Friction: reduces energy loss, extending lifespan.

Enhanced Wear Resistance: improved durability through advanced materials and manufacturing processes.

Self Aligning Ball Bearing

iron cage

brass cage

nylon cage

iron cage

rubber cage

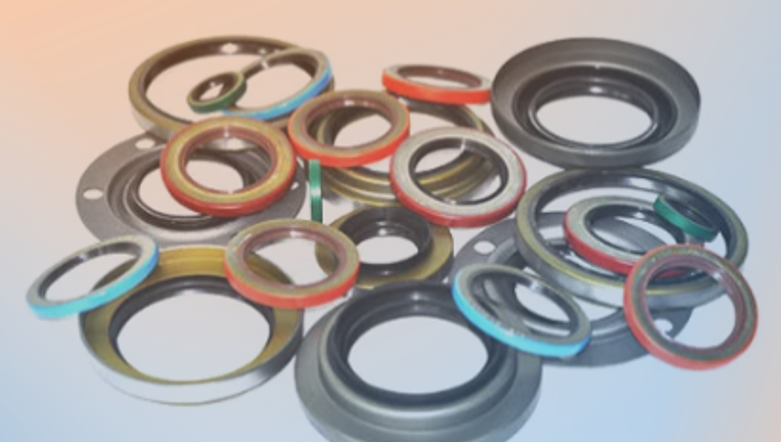

Needle Roller Bearing

Standard Seal

Sand Washing Machine

Screw Sand Washing Machine is a widely used, high-efficiency sand and gravel washing machine. Here are some of its key features and benefits:

Quality of Final Product: thoroughly removes impurities like dust, silt, and debris, resulting in cleaner and higher-quality sand.

Eco-Friendly: the water recycling feature helps in reducing water wastage, contributing to environmentally friendly operations.

Reduced Labor Costs: automated functions and high efficiency lower the need for manual intervention.

Wide Application: suitable for use in industries like mining, quarrying, construction, and recycling, where sand and gravel washing is essential.

Air Compressors Spare Parts

Air Filters: essential for keeping dust and contaminants from entering the compressor, ensuring clean air output

and protecting internal components.

Oil Filters: used in lubricated compressors to remove impurities from the oil, ensuring smooth operation.

Pressure Switches: regulate the pressure inside the compressor by controlling the start and stop of the motor.

Check Valves: prevent the backflow of air, ensuring the air flows in the correct direction during compression.

Gaskets: provide a seal between different parts of the compressor, preventing air or oil leaks.

Belts: transfer power from the motor to the compressor pump in belt-driven models.

Oil Separators: separate oil from the compressed air, especially important in rotary screw compressors.

Engine and Genset Parts

Filters: filter the air entering the genset engine to prevent dust and particles from damaging internal components.

Oil Filters: keep the oil clean by filtering out impurities, ensuring proper lubrication of engine components.

Fuel Filters: filter out dirt from the fuel to prevent damage to the fuel system and maintain engine efficiency.

Regulators: regulate and stabilize the output voltage during genset operation. ity from the rotor to the stator.

Pistons: main moving components that travel up and down inside the cylinder, converting heat energy from combustion.

Piston Rings: seal the gap between the piston and cylinder wall to prevent gas leaks.

Spark Plugs: ignite the fuel-air mixture in gasoline engines.

Fuel Injectors: spray fuel into the combustion chamber in diesel engines.

Head Gaskets: seal the combustion chamber and prevent coolant or oil from leaking between the engine block and cylinder.

After-sales service

Comprehensive After-sales Service: free repairs, product replacement, and detailed technical support to keep your bearing products running smoothly.

Rapid Response Mechanism: our professional team is poised to resolve any issues swiftly and efficiently.

Convenient Contact Options: our customer service is available around the clock via phone, email, or online chat for your convenience.

Active Feedback Listening: we welcome and value your feedback, promising attentive consideration for every comment.

Professional Maintenance Advice: providing maintenance and care guidelines to help extend the lifespan and efficiency of your products.